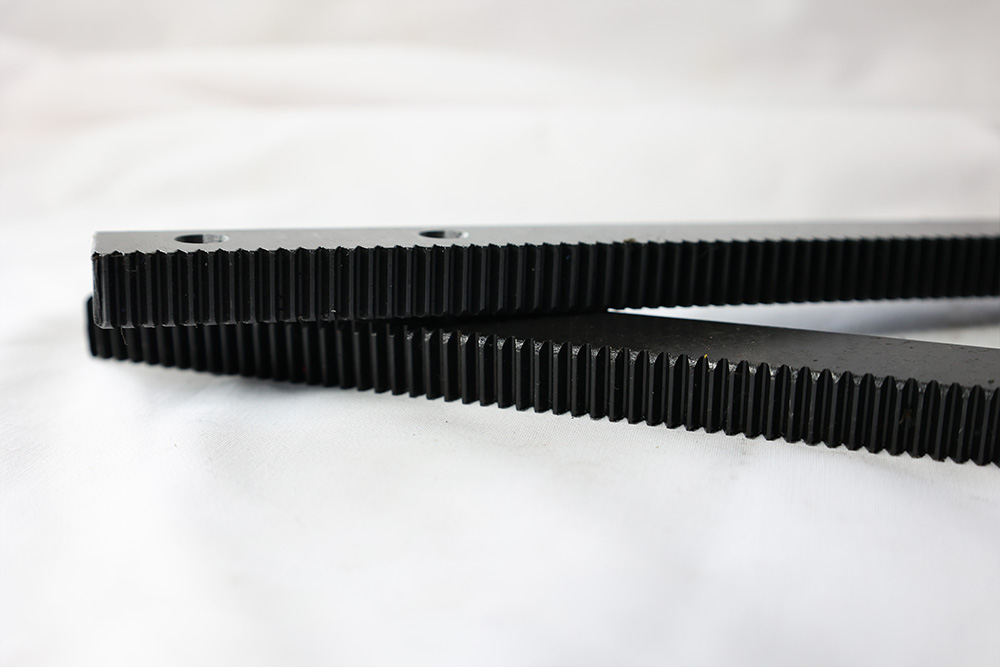

What are the processing methods of the rack?

The rack is divided into helical rack and straight rack, which are used together with helical cylindrical gear and straight cylindrical gear respectively. The tooth profile of the rack is straight rather than involute, which is equivalent to an infinite cylindrical gear. There are many ways to process the rack, each of which is based on different materials and requirements for rack accuracy.

There are mainly two ways to process the rack. For some racks with high accuracy and high hardness, including heat treatment of materials, tooth profile processing, etc., two wire cutting tooth profile and two tooth profile heat treatment are used. The first heat treatment is used to eliminate the internal stress of the rack material, and then the first wire cutting of the tooth profile is carried out, leaving 2mm margin for the tooth profile; For the second time, heat treatment is adopted to make the hardness of the tooth profile meet the requirements for use. Then, the copper layer is overlaid on both ends of the rack. After turning the line and grinding the outer circle, the tooth profile is cut for the second time to reach the level where the rack is coaxial with the outer circle. After these two heat treatments and two wire cutting cycles of the rack, the rack can not only overcome the problem of hardenability of the material after heat treatment, but also meet the requirements of hardness, ensure the high accuracy of the tooth profile, and improve the coaxiality of the tooth profile and the outer circle. So this method has a great advantage, which is to ensure that the overall hardness of the tooth profile can meet the requirements, while making the accuracy of the tooth profile meet the design requirements, so that the processing quality of the rack is greatly improved.

Rack processing largely determines the hardness and accuracy of the rack, so we should strictly control the whole process of rack processing to ensure that the processed products can meet the requirements of use